As we aim for manufacturing practices that are more environmentally conscious and socially responsible, it’s important to find innovative solutions that benefit both the planet and the workers. One solution is the reduction of industrial fluid usage in the metal stamping industry. Reducing fluid consumption offers financial and ethical advantages and promotes environmental conservation and a healthier workplace for employees.

As we aim for manufacturing practices that are more environmentally conscious and socially responsible, it’s important to find innovative solutions that benefit both the planet and the workers. One solution is the reduction of industrial fluid usage in the metal stamping industry. Reducing fluid consumption offers financial and ethical advantages and promotes environmental conservation and a healthier workplace for employees.

Benefits of Sustainable Manufacturing Practices

Sustainable manufacturing practices are pivotal in protecting our planet, aiming to minimize environmental impact while maximizing social and economic benefits. One important framework that guides manufacturers in their sustainability journey is ISO 14001 compliance. ISO 14001 helps manufacturers establish an effective environmental management system to minimize environmental impact and maximize social and economic benefits. Adhering to this standard can demonstrate commitment to reducing waste, energy consumption, and harmful emissions, which yields both financial and ethical advantages.

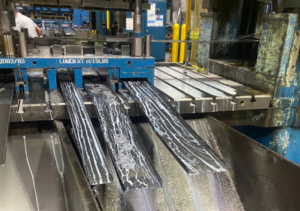

The Role of Fluid Reduction in Sustainable Manufacturing

Reducing industrial fluid use in the metal stamping industry brings significant environmental benefits. Consider the following:

- Conservation of natural resources: Manufacturers conserve valuable resources, such as water and energy, by minimizing fluid consumption.

- Efficient waste management: Reducing fluid usage overall significantly minimizes the generation of fluid waste. This not only helps in reducing costs related to waste disposal but also mitigates the risk of environmental contamination.

- Pollution reduction: By minimizing the need for fluid circulation and disposal, manufacturers can significantly reduce the potential for pollution incidents and the release of hazardous chemicals into the environment.

- Greenhouse gas emissions reduction: Fluid production and disposal processes often involve energy-intensive activities that generate carbon emissions. By adopting efficient fluid usage practices, manufacturers can decrease their carbon footprint, helping to mitigate climate change.

Reducing Fluid Use for a Healthier Work Environment

Workers in the metal stamping industry face several health hazards from exposure to industrial fluids, including skin irritation, allergic contact dermatitis, irritation of the eyes, nose, and throat, and, occasionally, breathing difficulties such as bronchitis and asthma. By reducing fluid usage, manufacturers can minimize worker exposure to these hazardous chemicals, improving worker health and well-being. Additionally, reducing fluid use decreases the concentration of airborne contaminants, resulting in better air quality within the workplace. This reduction in health risks and improved air quality create a safer and healthier work environment for metal stamping industry workers.

A healthier work environment for manufacturers can yield several advantages. It fosters worker retention and satisfaction, reducing turnover and recruitment expenses. Furthermore, a healthier work environment enhances employee well-being and morale, resulting in increased productivity, improved work quality, and greater job satisfaction.

Achieving Sustainable & Healthy Metal Stamping Operations

Reducing fluid consumption can lead to sustainable practices and improved worker well-being in metal stamping operations. Practical methods for reducing fluid usage include optimizing fluid application, implementing closed-loop systems, and monitoring and controlling fluid usage. Employee training and awareness programs are crucial in ensuring that workers understand the significance of fluid reduction and have the necessary knowledge and skills to implement best practices. Technology and equipment upgrades, such as advanced fluid management systems and automation, will also improve fluid use.

Reducing fluid use in the metal stamping industry contributes to sustainability and creates a healthier work environment for employees. Manufacturers can break the cycle of purchasing and disposing of large quantities of fluids by partnering with Impact Fluids. We focus on understanding your entire operation, identifying areas where the overuse of fluids affects your bottom line, and offering tailored solutions for improvement. By working with Impact Fluids, metal stamping organizations can reduce fluid usage leading to improved manufacturing practices, enhanced sustainability, and a healthier work environment.

Take the first step towards a more efficient and sustainable future. Let’s talk!