Impact Fluids News & Articles

Diagnosing Common Fluid Management Mistakes

Optimizing fluid management in metalworking facilities is crucial for enhancing operational productivity, ensuring environmental compliance, and reducing operational costs. However, many facilities encounter common issues with fluid management that can significantly impede their performance. These challenges often include inconsistent fluid mixing leading to poor part quality and increased waste, improper selection of metalworking fluids resulting…Read the rest of this entry »

Optimize Efficiency and Enhance Worker Safety with Fluid Reduction in Metalworking

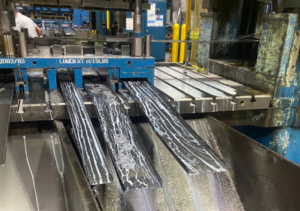

Strategic Selection and Reduction of Fluids to Enhance Safety and Sustainability in Metalworking Operations Metalworking fluids like stamping fluids, coolants, and cleaners are essential to the metal manufacturing industry. These unsung heroes ensure our machinery operates smoothly, our products meet the highest standards, and our processes stay efficient. However, as with many industrial processes, improper…Read the rest of this entry »

How Inferior Metalworking Fluids Increase Operational Costs

The phrase “you get what you pay for” rings particularly true when it comes to the quality of metalworking fluids used in metalworking processes. For operations managers, production supervisors, and others responsible for maintaining optimal operational efficiency, the choice of fluids is a strategic investment in the health of your people, the performance of your…Read the rest of this entry »

Navigating the World of Aerospace Manufacturing: The Essential Role of Process Fluids

Precision and Sustainability with Hangsterfer’s and Impact Fluids Aerospace manufacturing is a meticulous process where every component must adhere to strict performance and safety specifications. Specialized process fluids play a pivotal role in ensuring the high quality and reliability demanded by this industry. Essential for tool life, lubrication, and rust prevention, process fluids are vital…Read the rest of this entry »

The Best Fluid For Your Metalworking Application

At Impact Fluids, we understand the critical role that metalworking fluids play in the efficiency and success of your operations. With our comprehensive range of specialized fluids, we’re committed to delivering solutions tailored to your specific metalworking processes. Through our partnerships with industry leaders Curtis Fluids, Fortech Fluids, and Hangsterfer’s Labs, we ensure that you…Read the rest of this entry »

It’s Time to Reevaluate Your Metalworking Fluid Supplier

It’s Time to Reevaluate Your Metalworking Fluid Supplier At Impact Fluids, we know that metalworking fluids are critical to our customers’ success. The right fluids optimize machining and stamping performance and quality, while the wrong fluids lead to inefficiency, downtime, and waste. As your fluid supplier, we take this responsibility seriously.

Making An Impact in the Manufacturing Industry

In honor of National Manufacturing Day on October 6th, we celebrate the vital role of the manufacturing industry in building our nation. As a leader in metalworking fluid management for over 30 years, Impact Fluids knows firsthand how investing in domestic manufacturing drives America’s growth.

Maximizing Efficiency: Does Your Metalworking Facility Have the Proper Fluid Mixing and Application Systems in Place?

In the fast-paced manufacturing world, efficiency, cost reduction, and sustainability are critical for success. Central to achieving these goals is effective metalworking fluid management. Proper mixing and application systems are vital in optimizing fluid usage, ensuring smooth operations, and minimizing waste.

Reducing Industrial Fluid Use: A Win for Both the Environment and Worker Health

As we aim for manufacturing practices that are more environmentally conscious and socially responsible, it’s important to find innovative solutions that benefit both the planet and the workers. One solution is the reduction of industrial fluid usage in the metal stamping industry. Reducing fluid consumption offers financial and ethical advantages and promotes environmental conservation and…Read the rest of this entry »