The use of fluids in metal stamping and machining operations is necessary, but with their use comes the corporate responsibility to collect and dispose of fluid waste properly. Used metalworking fluids become contaminated with oils, fines, metals, bacteria, etc. These fluids require treatment before disposal to meet local, state, and federal laws, and even then, there are still environmental impacts associated with transportation and proper disposal. Not to mention the cost.

The use of fluids in metal stamping and machining operations is necessary, but with their use comes the corporate responsibility to collect and dispose of fluid waste properly. Used metalworking fluids become contaminated with oils, fines, metals, bacteria, etc. These fluids require treatment before disposal to meet local, state, and federal laws, and even then, there are still environmental impacts associated with transportation and proper disposal. Not to mention the cost.

The best way to reduce environmental impact is to reduce industrial fluid usage. Adopting sustainable fluid management practices can reduce costs and help companies meet regulatory requirements and certifications, like ISO 14001, enhance their reputation, and increase their competitiveness in the marketplace.

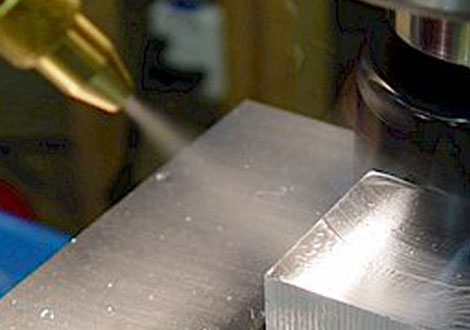

Flood coolant systems, where a constant stream of coolant is applied during cutting applications, have long been the choice of manufacturers to lubricate, disperse heat, and remove chips to prevent tool wear and improve part quality. Flood cooling requires enough fluid to immerse the entire cutting zone completely. While flood cooling works, premier manufacturing organizations must continuously look at ways to improve their production methods to stay competitive in a global market.

Flood coolant systems, where a constant stream of coolant is applied during cutting applications, have long been the choice of manufacturers to lubricate, disperse heat, and remove chips to prevent tool wear and improve part quality. Flood cooling requires enough fluid to immerse the entire cutting zone completely. While flood cooling works, premier manufacturing organizations must continuously look at ways to improve their production methods to stay competitive in a global market.

There is a time and a place for friction. Without friction, we wouldn’t be able to walk, drive a car, write on paper, hammer a nail into a wall, or warm up our hands by rubbing them together. But too much friction in a stamping or metalworking process has profound implications, from tool wear to scrapping parts. Thanks to

There is a time and a place for friction. Without friction, we wouldn’t be able to walk, drive a car, write on paper, hammer a nail into a wall, or warm up our hands by rubbing them together. But too much friction in a stamping or metalworking process has profound implications, from tool wear to scrapping parts. Thanks to

Stampers would be well-served to close the loop on waste and increase awareness of and accounting for all of the soft costs associated with lubricant waste, in addition to the more obvious hard costs.

Stampers would be well-served to close the loop on waste and increase awareness of and accounting for all of the soft costs associated with lubricant waste, in addition to the more obvious hard costs.