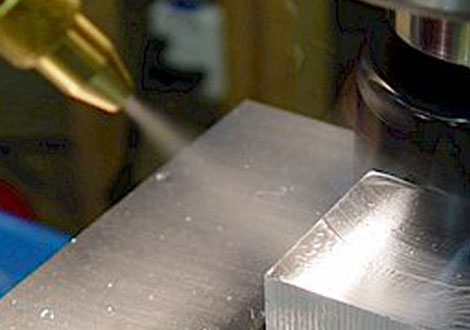

Flood coolant systems, where a constant stream of coolant is applied during cutting applications, have long been the choice of manufacturers to lubricate, disperse heat, and remove chips to prevent tool wear and improve part quality. Flood cooling requires enough fluid to immerse the entire cutting zone completely. While flood cooling works, premier manufacturing organizations must continuously look at ways to improve their production methods to stay competitive in a global market.

Flood coolant systems, where a constant stream of coolant is applied during cutting applications, have long been the choice of manufacturers to lubricate, disperse heat, and remove chips to prevent tool wear and improve part quality. Flood cooling requires enough fluid to immerse the entire cutting zone completely. While flood cooling works, premier manufacturing organizations must continuously look at ways to improve their production methods to stay competitive in a global market.

Ima Admin

Ima Admin

Top Three Benefits of Using Less Metalworking Fluid in Your Stamping Process

There is a time and a place for friction. Without friction, we wouldn’t be able to walk, drive a car, write on paper, hammer a nail into a wall, or warm up our hands by rubbing them together. But too much friction in a stamping or metalworking process has profound implications, from tool wear to scrapping parts. Thanks to the work of Leonardo DaVinci, who was one of the first to experiment with fluids in his study of friction and machine operations, as well as countless inventors and physicists, today, we have a solid understanding of the impacts of friction and how to control it using metalworking fluids or stamping fluids.

There is a time and a place for friction. Without friction, we wouldn’t be able to walk, drive a car, write on paper, hammer a nail into a wall, or warm up our hands by rubbing them together. But too much friction in a stamping or metalworking process has profound implications, from tool wear to scrapping parts. Thanks to the work of Leonardo DaVinci, who was one of the first to experiment with fluids in his study of friction and machine operations, as well as countless inventors and physicists, today, we have a solid understanding of the impacts of friction and how to control it using metalworking fluids or stamping fluids.

Stampers would be well-served to close the loop on waste and increase awareness of and accounting for all of the soft costs associated with lubricant waste, in addition to the more obvious hard costs.

Stampers would be well-served to close the loop on waste and increase awareness of and accounting for all of the soft costs associated with lubricant waste, in addition to the more obvious hard costs.

The purchase price of the fluid is just the tip of the iceberg – ‘the costs above the water’, but you need to consider those hidden costs below the water that you can’t necessarily see so easily.