Armstrong International, headquartered in Three Rivers, MI., is a manufacturer of thermal utility systems components. They are a 5th generation, family-owned business committed to conserving energy and providing the best possible work environment for their employees. As part of that commitment, their process engineering department came to Impact Fluids looking for a solution to better control their stamping oil and fluid usage to reduce waste and improve safety for their operators.

More Fluid Is Not Better

Armstrong International stamps deep draw stainless steel cups for their steam traps. This is a difficult application for fluids, and the philosophy was often “more is better”.

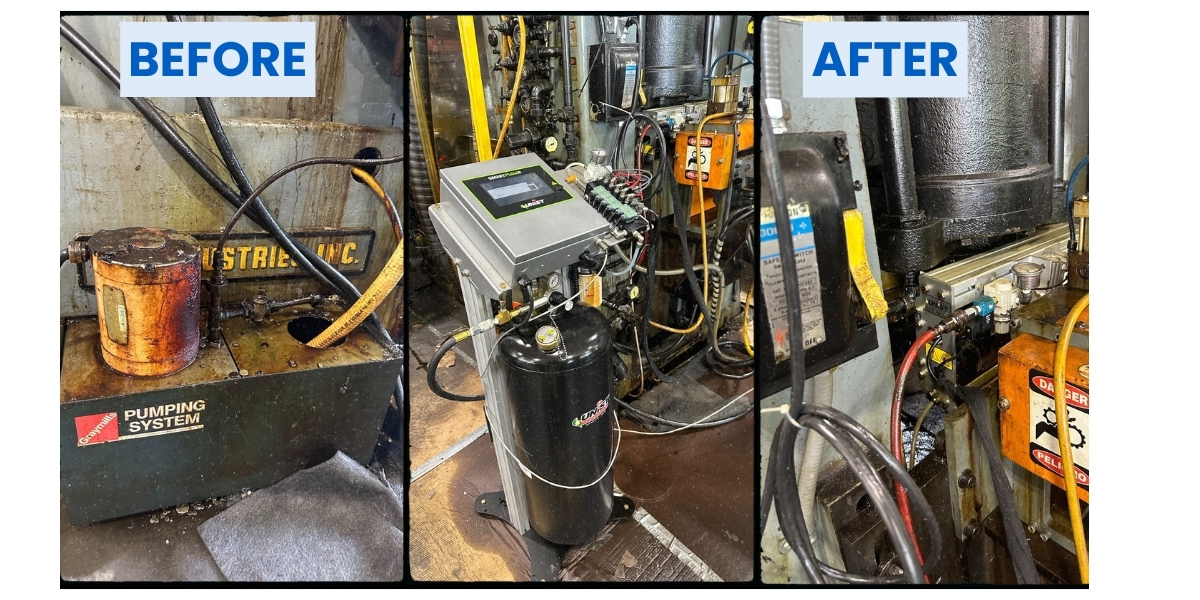

We used our Fluids Lifecycle Analysis and looked specifically at application systems, fluids and processes. Their existing system was a poorly designed roller system that flooded the stock and tried to wipe it off before going into the press. There was no consistency, so over-oiling was the operative choice.

Key Issues and Challenges: Fluid Waste, Safety Hazards & Downtime

- Significant waste coming off the bolster and die

- Excess oil on the floor from poor spray application downstream

- Excess oil in the air and especially on the floor causing slip issues and hazardous air quality

- Inconsistent die life issues

- Regular pumping of their pits below the press.

- Parts washing system was overburdened with excess oil

- There was press downtime for the operator to fill the application system 3-5 times per day

Our Solution: Fluid Reduction Plan and Unist Application System

Our solution was a new, Unist application system that included a roller and downstream spray nozzles. The Unist system is able to apply a very uniform amount of fluid across the entire width of the stock top and bottom. We then applied a small amount of fluid downstream in the middle of the deep draw process for additional lubrication.

The Results: Reduced Waste and Fluid Usage while Improving Efficiency, Safety and Tool Life

- Reduced overall fluid usage by 60+%.

- This eliminated oil on the floor making the area safer for operators.

- Mist in the air was reduced significantly.

- Tool life was improved because now they are applying fluid to the bottom of the stock uniformly.

- Cleaner wash system for better parts cleaning.

- The operator now only fills the application system every 2-3 days which yields more press uptime.

Our Work Continues

We continue to work with Armstrong on fluid alternatives to further reduce their waste and impact their bottom line.